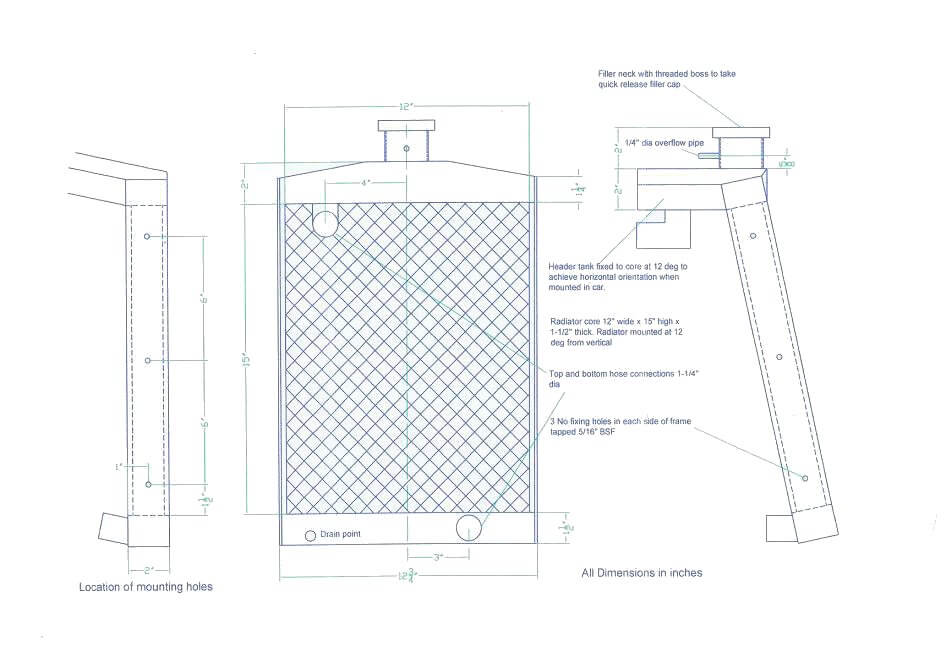

Following a telephone conversation with a vintage sports car owner from Surrey, we received the drawing (shown below) asking if we would be able to produce this radiator for his car. After lengthy discussions with the client, we offered to have the radiator collect by our courier and bought back to our workshops. The client decided to drive to our workshops and deliver the radiator in person. It was good to meet up face to face and discuss the requirements. He left with us the cars existing radiator and the mounting frame that secured it to the car.

The vehicle was a very nice 1935 Riley sports car which at some time in its past had the original radiator changed for a nineteen fifties Morris JU250 van radiator. The original Radiator brass threaded neck had been soldered onto the Morris radiator to enable the chrome cap to be fitted when the radiator was inside the chrome grille.

The picture to the left shows the old Morris van radiator alongside the completed new radiator that we have manufactured.

We studied the drawing and realised that it would be challenging to get a sloping core into a horizontal top tank, with a large overhanging header and maintain a level top tank whilst having a leaning core.

A high efficiency, multi louvred gill on tube core was manufactured with a large top tube plate to accommodate the new header tank. The brass top and bottom tanks were folded up, shaped as per the drawings and silver soldered together. The core tube plates had to be teased out to an angle to get the radiator to lean back whilst allowing for the top water tank to be level. Once all of the construction had taken place the two water tanks were soft soldered onto the new radiator core. The top inlet was made with a 90 degree mitre and the two halves were silver soldered together. A swage was roller into the end of the inlet tube to secure the rubber hose. The bottom outlet was made with the same method but without the 90 degree angle. Both tubes were soldered to the water tanks. The steel sides were manufactured by folding steel into a “C” section that was drilled and fitted with caged nuts. We ensured that holes lined up with the existing radiator mounting frame from the client.

The brass ring was removed from the old Morris van radiator and fitted to the new radiator. Care was taken to ensure that a tailor fit was achieved into the Riley chromed shell. Finally, the radiator was removed from the shell, masking taped up and sprayed with black radiator paint. The radiator was refitted into the shell and the finished radiator was returned to the client for fitting to the vehicle. With the increased head of water in the larger top tank and the multi louvred fin copper in the new core, the owner found that this unpressurised cooling system ran at a much lower temperature.